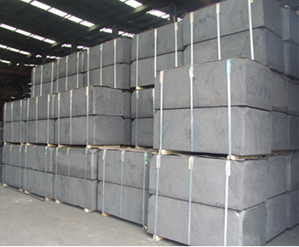

1.Photos of product

2.Introduction and main application

Pre-baked anode is made of green petroleum coke,pitch coke as aggregate and coal pitch as binder,using as anode materials for aluminum reduction cell.This kind of carbon block has been roasted with stable geometry,so it is also called pre-baked carbon anode blocks and aluminium electrolysis carbon anode.Pre-baked anode cells which use pre-baked carbon anode blocks as anode of aluminum electrolyzer are modern large-scale aluminum reduction cell.

Strong direc curren(60-300ka)passed pre-baked carbon anode which is usually installed above the reduction cell,and then is filled with electrolysis.With 50-70μΩ.m of the resistivity of baked anodic caibon plus the resistivity of rods and iunction.In the normal production of aluminum electrolysis,the voltage of consumption baked anodic carbon drops to 300-500mV,which accounts for 10%-15% of the voltage that reduction cell drops.

Complicated electrochemical reaction of Decomposition of alumina (anode reaction) happens at the contact site of bottom of baked anodic carbon and melten electrolyte.Under the participation of carbon,the finalproduct of anode is carbon monoxide and carbon dioxide.In the production of alumimun electroysis,the main contents of anode work is the addition of new anode paste in the top of reduction cell and the replacement of pre-baked anode regularly as the daily average consumption of baked anodic carbon is 1-2cm to ensure normal continous work of anode.

3.Qulity index

| Content |

Quality index |

| Volume density |

>1.55gm/cc |

| Bulk density |

>2.06gm/cc |

| Resistivity |

<57 |

| Compressive strength |

>35Mpa |

| Ash |

<0.5% |

| Si |

<0.45% |

| Fe |

<0.45% |

| Ni |

<0.03% |

| V |

0.003-0.3% |

| Na |

0.04 |

| S |

0.5-3.2% |

| CO2reactivity loss |

>87% | |